By John Baker, Total Safety Certified Industrial Hygienist

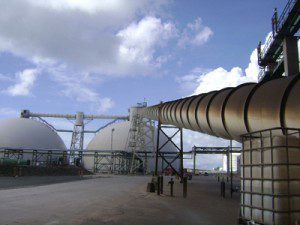

Petroleum coking is an environmentally responsible recycling process used in some oil refineries to make the most use of hydrocarbon residuals that otherwise would go to waste. As safety and health professionals, we are sure to control the high temperature and pressure used in the coke domes to “bake” the volatiles out of the coke and the drill and high pressure water sprays used to cut the coke out of the coke domes. However, critical safety and health hazards are present in the material handling processes used to move petroleum coke to storage and ultimately, to the customer. Enclosed conveyors are often used to move the coke into a storage building and then onto docks for loading onto barges, ships or to land based transportation loading facilities. The rollers moving the conveyor belt, the motors powering the rollers, vibrating screens and the limited space for personnel movement and access within the conveyor structure all present potential physical and electrical hazards which must be addressed in the Job Safety Analysis for production and maintenance tasks. Personnel must perform constant maintenance of the conveyors, often spending a considerable portion of a work shift crawling under conveyors to vacuum or sweep and shovel spillage. Even if the vacuum system is in top condition, the awkward space constraints of the conveyor gallery present ergonomic challenges that must be reviewed on a case-by-case basis.

Petroleum coking is an environmentally responsible recycling process used in some oil refineries to make the most use of hydrocarbon residuals that otherwise would go to waste. As safety and health professionals, we are sure to control the high temperature and pressure used in the coke domes to “bake” the volatiles out of the coke and the drill and high pressure water sprays used to cut the coke out of the coke domes. However, critical safety and health hazards are present in the material handling processes used to move petroleum coke to storage and ultimately, to the customer. Enclosed conveyors are often used to move the coke into a storage building and then onto docks for loading onto barges, ships or to land based transportation loading facilities. The rollers moving the conveyor belt, the motors powering the rollers, vibrating screens and the limited space for personnel movement and access within the conveyor structure all present potential physical and electrical hazards which must be addressed in the Job Safety Analysis for production and maintenance tasks. Personnel must perform constant maintenance of the conveyors, often spending a considerable portion of a work shift crawling under conveyors to vacuum or sweep and shovel spillage. Even if the vacuum system is in top condition, the awkward space constraints of the conveyor gallery present ergonomic challenges that must be reviewed on a case-by-case basis.

A potentially catastrophic hazard which must be controlled in coke handling operations is the possibility of a combustible dust explosion or deflagration. Petroleum coke is readily able to form dust clouds of finely divided, combustible material. OSHA’s National Emphasis Program for Combustible Dust (CPL-03-00-008) emphasizes the need for administrative and engineering controls including immediate housekeeping, prevention of ignition sources, ventilation with spark detection and explosion/deflagration suppression systems, explosion venting and other pressure relief devices, when a combustible dust layer exceeds 1/32 of an inch (about the thickness of a typical paper clip) on more than 5% of the floor area of a facility or any given room.

Total Safety studied the dust exposure potential of a petroleum coke handling operation at a large refinery that shipped its coke on ocean going vessels. Particle size analysis of the bulk coke product indicated that throughout the material handling process, more than 65% was smaller than the 40 mesh or 425 micrometer size that OSHA, NFPA and other authorities use as a first step in assessing the potential to form a combustible dust cloud. The bulk coke had less than 5 percent in the “respirable” particle size range of 4 micrometers; however the dust which wafted off the bulk material at transfer points as measured by an optical particle counter indicated that the majority of the airborne dust was in the “respirable” range. Personal samples of airborne dust were collected on filters connected to air sampling pumps worn by each worker. The filter cassettes were wrapped in aluminum foil before sampling and kept refrigerated afterward to prevent degradation of the collected chemicals. The collected dust was weighed and then chemically analyzed for “coal tar pitch volatiles (CTPV).” Two of the samples exceeded 0.2 milligrams of CTPV per cubic meter of air and were further analyzed for specific compounds within the “polyaromatic hydrocarbon (PAH)” chemical category. Neither sample showed any detectable amounts of PAH compounds. NIOSH approved half mask respirators with P100 filters provided adequate protection if properly worn according to manufacturer’s recommendations.

In summary, petroleum coke is an economically important recycled material which can be managed in a safe and healthful manner when the associated hazards are anticipated, recognized, evaluated and controlled in a systematic program.

For additional information regarding the health and safety of your workplace, call us at 888.44.TOTAL.